Author: WECC REMTF[1]

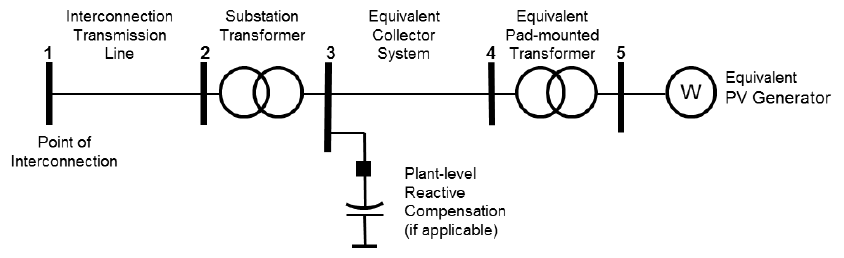

This article contains a general description of the WECC generic models based on REMTF technical specifications approved by WECC. The models are available as standard-library models in commercial simulation platforms used in WECC. The purpose of this document is to help model users understand the limitations of the models, the model structure, user-selectable options, requirements for scaling the plant size, and representation of protection settings.

Contents

Technical Specifications for the WECC Generic Models

The WECC generic models for PV plants are based on the following technical specifications:

- The models shall be non-proprietary and accessible to transmission planners and grid operators without the need for non-disclosure agreements.

- The models shall provide a reasonably good representation of dynamic electrical performance of solar photovoltaic power plants at the point of interconnection with the bulk electric system, and not necessarily within the PV power plant collector system.

- The models shall be suitable for studying system response to electrical disturbances, not solar irradiance transients (i.e., available solar power is assumed constant through the duration of the simulation). Electrical disturbances of interest are primarily balanced transmission grid faults (external to the solar PV power plant), typically 3 – 9 cycles in duration, and other major disturbances such as loss of generation or large blocks of load.

- Plant owners, inverter manufacturers and model users (with guidance from the integrators and manufacturers) shall be able to represent differences among specific inverter and/or plant controller responses by selecting appropriate model parameters and feature flags.

- Simulations performed using these models typically cover a 20-30 second time frame, with integration time steps in the range of 1 to 10 milliseconds.

- The models shall be valid for analyzing electrical phenomena in the frequency range of zero to approximately 10 Hz.

- The models shall incorporate protection functions that trip the associated generation represented by the model, or shall include the means for external modules to be connected to the model to accomplish such generator tripping.

- The models shall be initialized from a solved power flow case with minimal user intervention required in the initialization process.

- Power level of interest is primarily 100% of plant nominal rating. However, performance shall be valid, within a reasonable tolerance, for the variables of interest (current, active power, reactive power and power factor) within a range of 25% to 100% of rated power.

- The models shall perform accurately for systems with a short circuit ratio of 3 and higher at the point of interconnection. However, it should be noted that these generic models are NOT intended for studying parts of the system that are subject to very low short-circuit levels. In such cases, detailed vendor specific models may be needed.

- External reactive compensation and control equipment (i.e., external to the PV inverters) shall be modeled separately using existing WECC-approved models.

WECC approved the use of two generic dynamic models for PV plants: (a) a model consisting of plant controller, electrical controls and grid interface modules, intended for large-scale PV plants, and (b) a simplified model intended for distribution-connected, aggregated PV plants.

WECC Generic Model for Large-scale PV Plants

Model Structure

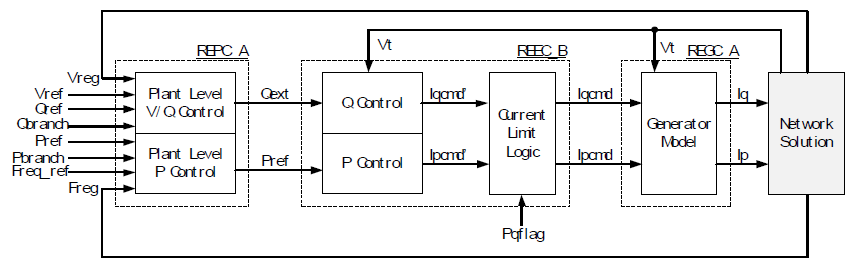

Dynamic representation of large-scale PV plants requires the use of three new renewable energy (RE) modules listed below. These modules, in addition to others, are also used to represent wind and PV power plants. It is required that the PV plant be modeled in power flow, preferably using the single-generator equivalent system.

- REGC_A module, used to represent the Generator/Converter (inverter) interface with the grid. It processes the real and reactive current command and outputs of real and reactive current injection into the grid model.

- REEC_B module, used to represent the Electrical Controls of the inverters. It acts on the active and reactive power reference from the REPC_Amodule, with feedback of terminal voltage and generator power output, and provides real and reactive current commands to the REGC_A module. REEC_B module is a simplified version of the REEC_A module used in wind models.

- REPC_A module, used to represent the Plant Controller. It processes voltage and reactive power output to emulate volt/var control at the plant level. It also processes frequency and active power output to emulate active power control. This module provides active reactive power command to the REEC_B module.

These modules do not include inverter or plant protection. However, existing generator protection models can be used to represent time-delayed voltage and frequency protection settings. The plant controller and protection modules are optional. Although the internal implementation may differ across simulation platforms, the modules have the same functionality and parameter sets.

| Module | PSLF™ modules | PSS®E modules | PowerWorld |

|---|---|---|---|

| Grid interface | regc_a | REGCAU1 | regc_a |

| Electrical controls | reec_b | REECBU1 | reec_b |

| Plant controller (optional) | repc_a | REPCAU1 | repc_a |

| Voltage/frequency protection (optional) | lhvrt / lhfrt | VRGTPA / FRQTPA | lhvrt / lhfrt |

Strictly speaking, only the REGC_A is required to run a simulation; however, the rest of the modules are needed to enable control functionality.

Model Call

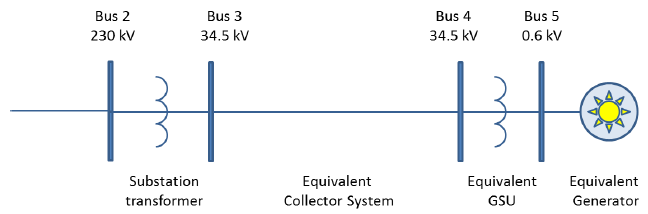

The model call varies according to the software platform. Users must follow the instructions provided with the model documentation. The model calls shown below for the various software platforms refer to the simple test system shown in figure on the right. This example is for a plant rated 110 MVA plant, which would correspond to a PV plant rated 100 MW and inverters sized for 0.95 leading or lagging power factor at rated power and rated voltage. In this particular hypothetical example, the equivalent generator is controlling voltage at bus 5.

| GE PSLF™ |

|---|

| regc_a 5 “Test” 0.6 “1 ” : #9 mvab=111. “lvplsw” 1. “rrpwr” 10.0 “brkpt” 0.9 “zerox” 0.4 “lvpl1” 1.22 “vtmax” 1.2 “lvpnt1” 0.8 “lvpnt0” 0.4 “qmin” -1.3 “accel” 0.7 “tg” 0.02 “tfltr” 0.02 “iqrmax” 999. “iqrmin” -999. “xe” 0.

reec_b 5 “Test” 0.6 “1 ” : #9 “mvab” 0. “vdip” -99. “vup” 99. “trv” 0.02 “dbd1” -0.5 “dbd2” 0.5 “kqv” 0. “iqh1” 1.5 “iql1” -1.5 “vref0” 0. “tp” 0.5 “qmax” 0.4 “qmin” -0.4 “vmax” 1.1 “vmin” 0.9 “kqp” 0.0 “kqi” 0.1 “kvp” 0.1 “kvi” 40. “tiq” 0.2 “dpmax” 999. “dpmin” -999. “pmax” 1. “pmin” 0. “imax” 1.3 “tpord” 0.4 “pfflag” 0. “vflag” 1. “qflag” 1. “pqflag” 0. repc_a 5 “Test” 0.6 “1 ” : #9 “mvab” 0. “tfltr” 0.2 “kp” 18. “ki” 5. “tft” 0. “tfv” 0.15 “refflg” 1. “vfrz” -1. “rc” 0. “xc” 0. “kc” 0. “vcmpflg” 1. “emax” 999. “emin” – 999. “dbd” 0. “qmax” 0.44 “qmin” -0.44 “kpg” 0.1 “kig” 0.5 “tp” 0.25 “fdbd1” 0. “fdbd2” 0. “femax” 999. “femin” -999. “pmax” 999. “pmin” -999. “tlag” 0.1 “ddn” 20. “dup” 0.0 “frqflg” 0. |

| PowerWorld Simulator |

| regc_a 5 “Test” 0.6 “1 ” : #1 mva=111. “lvplsw” 1. “rrpwr” 10. “brkpt” 0.9 “zerox” 0.4 “lvpl1” 1.22 “vtmax” 1.2 “lvpnt1” 0.8 “lvpnt0” 0.4 “qlim” -1.3 “accel” 0.7 “tg” 0.02 “tfltr” 0.02 “iqrmax” 999. “iqrmin” -999. “xe” 0.

reec_b 5 “Test” 0.6 “1 ” : #1 “mvab” 0. “vdip” -99. “vup” 99.0 “trv” 0.02 “dbd1” -0.5 “dbd2” 0.5 “kqv” 0. “iqh1” 1.5 “iql1” -1.5 “vref0” 0. “iqfrz” 0.15 “thld” 0. “thld2” 0. “tp” 0.5 “qmax” 0.4 “qmin” -0.4 “vmax” 1.1 “vmin” 0.9 “kqp” 0. “kqi” 0.1 “kvp” 0.1 “kvi” 40. “vref1” 0. “tiq” 0.2 “dpmax” 999. “dpmin” -999. “pmax” 1. “pmin” 0. “imax” 1.3 “tpord” 0.4 “pfflag” 0. “vflag” 1. “qflag” 1. “pflag” 0. “pqflag” 0. repc_a 5 “Test” 0.6 “1 “: #1 “mvab” 0. “tfltr” 0.2 “kp” 18. “ki” 5. “tft” 0. “tfv” 0.15 “refflg” 1. “vfrz” -1. “rc” 0. “xc” 0. “kc” 0. “vcmpflg” 1. “emax” 999. “emin” -999. “dbd” 0. “qmax” 0.44 “qmin” -0.44 “kpg” 0.1 “kig” 0.5 “tp” 0.25 “fdbd1” 0. “fdbd2” 0. “femax” 999. “femin” -999. “pmax” 999. “pmin” -999. “tlag” 0.1 “ddn” 20. “dup” 0. “frqflg” 0. |

| Siemens PTI PSS®E |

| 5 ‘USRMDL’ 1 ‘REGCAU1’ 101 1 1 14 3 4 1 0.20000E-01 10.000 0.90000 0.50000 1.2200 1.2000 0.80000 0.40000 -1.3000 0.20000E-01 0.70000 9999.0 -9999.0 1.0000/

5 ‘USRMDL’ 1 ‘REECBU1’ 102 0 5 25 6 4 0 0 1 1 0 -99.000 99.000 0.0000 -0.50000E-01 0.50000E-01 0.0000 1.0500 -1.0500 0.0000 0.50000E-01 0.43600 -0.43600 1.1000 0.90000 0.0000 0.10000 0.0000 40.000 0.20000E-01 99.000 -99.000 1.0000 0.0000 1.8200 0.20000E-01 / 5 ‘USRMDL’ 1 ‘REPCAU1’ 107 0 7 27 7 9 2 0 0 ‘0 ‘ 1 1 0 0.20000E-01 18.000 5.0000 0.0000 0.75000E-01 0.0000 0.0000 0.0000 0.20000E-01 0.10000-0.10000 0.0000 0.0000 0.43600 -0.43600 0.10000 0.50000E-01 0.25000 0.0000 0.0000 999.00 -999.00 999.00 -999.00 0.10000 20.000 0.0000 / |

The parameters shown are intended for model testing only, and do not represent the performance of any particular PV plant or equipment.

Scaling for the PV plant size and reactive capability

Model parameters are expressed in per unit of the generator MVA base (mvab parameter in the regc_a module in the example above). The specification of MVA base is implementation-dependent. For example, in the PSLF™ implementation, if the MVA base for those modules is zero, the MVA base entered for the REGC_A module applies to the electrical controls (REEC_B) and plant controller (REPC_A). A different MVA base can be specified for those modules, if desired.

To scale the dynamic model to the size of the plant, the generator MVA base parameter must be adjusted. The reactive range can be adjusted with the qmin and qmax parameters in the REEC_Bmodule. Normally, the MVA base and reactive limits are the same as those used in power flow, taking into consideration that the capability is being specified for the equivalent generator, not the point of connection.

Volt/Var controls options

The plant-level control module allows for the following reactive power control modes to be represented:

- Closed loop voltage regulation (V control) at a user-designated bus with optional line drop compensation, droop response and dead band.

- Closed loop reactive power regulation (Q control) on a user-designated branch, with optional dead band.

Different function calls are required to specify the regulated bus or branch. In the electrical control module, additional reactive control options are available:

- Constant power factor (PF), based on the generator PF in the solved power flow case

- Constant reactive power, based either on the equivalent generator reactive power in the solved power flow case or from the plant controller

- Defined reactive power injection during a user-defined voltage-dip event

Various combinations of plant-level and inverter-level reactive control are possible by setting the appropriate parameters and switches. Table bellow shows a list of control options, and the models and switches that would be involved. The entry “N/A” indicates that the state of the switch does not affect the indicated control mode.

| Functionality | Models Needed | PfFlag | Vflag | Qflag | RefFlag |

|---|---|---|---|---|---|

| Constant local PF control | REEC_B | 1 | N/A | 0 | N/A |

| Constant local Q control | REEC_B | 0 | N/A | 0 | N/A |

| Local (gen terminals) V control | REEC_B | 0 | 0 | 1 | N/A |

| Local coordinated V/Q control | REEC_B | 0 | 1 | 1 | N/A |

| Plant level Q control | REEC_B, REPC_A | 0 | N/A | 0 | 0 |

| Plant level V control | REEC_B, REPC_A | 0 | N/A | 0 | 1 |

| Plant level Q control + local coordinated V/Q control | REEC_B, REPC_A | 0 | 1 | 1 | 0 |

| Plant level V control + local coordinated V/Q control | REEC_B, REPC_A | 0 | 1 | 1 | 1 |

Active power control options

The plant controller allows a user to specify the active power control options listed below. Active power control modes as well as the models and parameters involved are shown bellow.

- Constant active power, based on the generator output in the solved power flow case

- Governor droop response with different characteristics for over and under frequency conditions, based on frequency deviation at a user-designated bus.

| Functionality | Models Needed | Freq_flag | Ddn | Dup |

|---|---|---|---|---|

| No governor response | REGC_A, REEC_B | 0 | N/A | N/A |

| Governor response with down regulation, only | REGC_A, REEC_B, REPC_A | 1 | > 0 | 0 |

| Governor response with up and down regulation | REGC_A, REEC_B, REPC_A | 1 | > 0 | > 0 |

In situations where current limit of the equivalent inverter is reached, the user can specify whether active or reactive power takes precedence, by setting the Pqflag parameter in the REEC_B module.

Representation of Voltage and Frequency Protection

Frequency and voltage tolerance is required for transmission-connected PV plants. Because they are simplified, the WECC generic models may not be suitable to fully assess compliance with voltage and frequency ride-through requirement. The same limitation applies to other positive-sequence models. Voltage ride-trough is engineered as part of the plant design, and requires far more sophisticated modeling detail than is possible to capture in a positive-sequence simulation environment. It is recommended that a standardized (existing) protection model with voltage and frequency thresholds and time delays can be used to indicate the minimum disturbance tolerance requirement that applies to the plant.

Sample simulation results

.png)

Figure on the right shows the results of a PV plant response to a 3-cycle fault bus 2, using the hypothetical test system and model parameters shown above. Transformer and equivalent generator parameters are as follows:

- GSU: R = 0.0 pu, X = 0.05 pu on 100 MVA base

- Station transformer: R = 0.0 pu, X = 0.1 pu on 100 MVA base

- Equivalent collector system: R = 0.015 pu, X = 0.025 pu, B = 0.01 pu on 100 MVA and 34.5 kV base

WECC Generic Model for Distributed and Small PV Plants

Model Structure

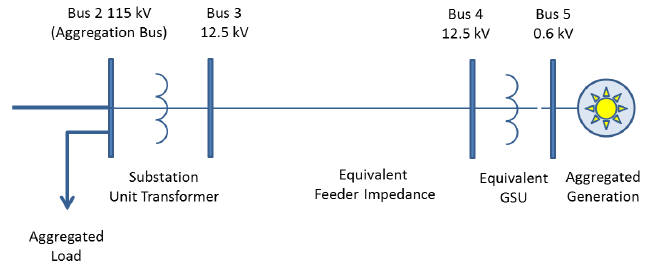

The generic model PVD1 is recommended to represent distribution-connected small PV plants or multiple PV plants aggregated at a high voltage bus that is represented in power flow. The PVD1 model is much simpler than the modules discussed for Large-scale PV Plants, and provides a basic set of control options. It requires that the PV generator be explicitly represented in power flow, preferably behind an equivalent transformer and feeder.

At its core, the PVD1 model is a simple current injection with the following basic functionality for reactive power control, active power control and protection.

Model Call

The model call varies according to the software platform. Users must follow the instructions provided with the model documentation. The example described below is for the PSLF™ platform, using the simple test system. This example would be applicable to a single distribution-connected PV plant or multiple distribution-connected PV systems with total capacity of 25 MW, deployed in the vicinity of a transmission bus (bus 2) where generation and load is aggregated. In this case, the aggregated generation is modeled behind an equivalent substation unit transformer and feeder impedance. Consideration should also be given to modeling the load behind the transformer and equivalent impedance.

| pvd1 5 “Test” 0.6 “1 ” : #1 mvab=28. “pqflag” 1. “xc” 0. “qmx” 0. “qmn” 0. “v0” 0.9 “v1” 1.1 “dqdv” 0. “fdbd” -99. “ddn” 0. “imax” 1.1 “vt0” 0.88 “vt1” 0.9 “vt2” 1.1 “vt3” 1.2 “vrflag” 1. “ft0” 59.5 “ft1” 59.7 “ft2” 60.3 “ft3” 60.5 “frflag” 0. “tg” 0.02 “tf” 0.05 “vtmax” 1.2 “lvpnt1” 0.8 “lvpnt0” 0.4 “qmin” -1.3 “accel” 0.7 |

The parameters shown are intended for model testing only, and do not represent the performance of any particular case.

Scaling for the PV plant size and reactive capability

To scale the dynamic model to the size of the aggregated PV generation, the generator MVA base MVA (mvab parameter in the example above) must be adjusted. In this case, fixed power factor was emulated by setting the reactive limits (qmin and qmax in the example above) to zero.

Volt/Var Controls

The model allows two basic reactive power control modes, listed below.

- Constant reactive power, based on generator output in the solved power flow case

- Volt/var control at the generator terminals, with user-defined Q versus V characteristic and optional line drop compensation

In the example above, volt/var control is disabled by setting the reactive range (Qmx and Qmn) to zero.

Active Power Controls

The model allows two basic active power control modes, listed below.

- Constant active power, based on generator output in the solved power flow case

- Over-frequency response, with user-defined dead band and droop

In the example above, frequency response is disabled by setting the droop gain parameter (Dbn) to zero; thus, the plant operates in constant active power mode.

Similar to the large-scale PV plant model, the user can specify whether active or reactive power takes precedence, by setting the Pqflag parameter.

Generation Tripping

The model allows for tripping of all or a portion of the generation based on over- and under- voltage and frequency monitored at the equivalent generator terminals. The user can set the voltage and frequency dead bands (vt1 to vt2 and ft1 to ft2, respectively), how much generation trips, and what fraction of the generation is restored as the disturbance subsides. In the example above, generation would disconnect outside the 0.9 to 1.1 pu voltage range, with all generation assumed to be disconnected when voltage goes below 0.88 or above 1.2 pu. Similarly, generation would disconnect when frequency is outside the range 59.7 Hz to 60.3 Hz, with all generation assumed to be disconnected when frequency goes below 50.5 Hz or above 60.5 Hz. In the example shown above, the parameters vfflag and frflag (labeled vr_recov and fr_recov) are set to 1 and 0, respectively. This means that, as voltage and frequency recover within the dead band, all of the generation disconnected on voltage reconnects, but none of the generation disconnected on frequency would reconnect.

Partial tripping is relevant when the equivalent generator represents distributed generation systems, each of which would experience a transmission-level disturbance very differently depending on the electrical distance to the bus where they are aggregated. At present, applicable interconnection requirements emphasize tripping requirements for off-nominal frequency and voltage, as opposed to fault ride-through capability. The REMTF is integrating distributed generation model into the existing WECC composite load model (CMPLDW), which would provide a better indication of conditions that distributed generation experience. This topic falls outside of this document.

It should be noted that trip thresholds in this model are not time-dependent. If this functionality is desired, a standard generator protection model can be used.

Sample Simulation Results

.png)

Figure on the right shows the results of a PV plant response to a 3-cycle fault bus 2, using the hypothetical test system and model parameters shown above. Transformer and equivalent generator parameters are as follows:

- GSU: R = 0.0 pu, X = 0.05 pu on 50 MVA base

- Station transformer: R = 0.0 pu, X = 0.1 pu on 50 MVA base

- Equivalent collector system: R = 0.015 pu, X = 0.025 pu, B = 0.01 pu on 50 MVA and 12.5 kV base

Summary

The PV plant generic models described in this article are intended for general bulk system planning studies. The general guidelines discussed here should be used in conjunction with the model documentation provided as part of the relevant simulation platform. Selection of appropriate model parameters requires consultation with inverter manufacturer and plant operator. PV plant dynamic modeling is an area of active research. As with any other model, the WECC generic PV plant models will evolve based on industry experience and technology evolution.

References

- ↑ WECC REMTF, WECC PV Power Plant Dynamic Modeling Guide, April 2014, [Online]. Available: https://www.wecc.biz/Reliability/WECC%20Solar%20Plant%20Dynamic%20Modeling%20Guidelines.pdf. [Accessed June 2015].