Author: Sandia National Laboratories[1]

Contents

- 1 Background

- 2 Review of Existing Reactive Power Standards

- 3 References

Background

Voltage on the North American bulk system is normally regulated by generator operators, which typically are provided with voltage schedules by transmission system operators. In the past, variable generation plants were considered very small relative to conventional generating units, and were characteristically either induction generator (wind) or line-commutated inverters (PV) that have no inherent voltage regulation capability. Bulk system voltage regulation was provided almost exclusively by synchronous generators. However, the growing level of penetration of non-traditional renewable generation – especially wind and solar – has led to the need for renewable generation to contribute more significantly to power system voltage and reactive regulation. For the most part, new wind plants use doubly fed asynchronous generators or full-conversion machines with self-commutated electronic interfaces, which have considerable dynamic reactive and voltage regulation capability. If needed to meet interconnection requirements, the reactive power capability of solar and wind plants can be further enhanced by adding of a static var compensator (SVC), static compensators (STATCOMS), and other reactive support equipment at the plant level. It should be noted that converters need to be sized larger to provide reactive power capability at full output. Currently, inverter-based reactive capability is more costly compared to the same capability supplied by synchronous machines. Partly for this reason, Federal Energy Regulatory Commission (FERC) stipulated in Order 661A (applicable to wind generators) that a site-specific study must be conducted by the transmission operator to justify the reactive capability requirement up to 0.95 lag to lead at the point of interconnection. For solar PV, it is expected that similar interconnection requirements for power factor range and low-voltage ride-through will be formulated in the near future. Inverters used for solar PV and wind plants can provide reactive capability at partial output, but any inverter-based reactive capability at full power implies that the converter need to be sized larger to handle full active and reactive current.

Nonetheless, variable generation resources such as wind and solar PV are often located in remote locations, with weak transmission connections. It is not uncommon for wind parks and solar PV sites to have short circuit ratios (i.e., ratios of three-phase short circuit mega volt-amperes (MVA) divided by nominal MVA rating of the plant) of 5 or less. Voltage support in systems like this is a vital ancillary service to prevent voltage instability and ensure good power transfer.

Voltage regulation in distribution systems is normally performed at the distribution substation level and distribution voltage regulation by distributed resources is not allowed by IEEE 1547. Normally, distributed resources operate with fixed power factor with respect to the local system.

Reactive Capability of Synchronous Generators

Customarily, when reactive capability of variable generation resources is specified for transmission interconnections, it is done at the point of interconnection (POI), which is the point at which power is delivered to the transmission system. This is often (but not always) at the high side of the main facility transformer. A typical requirement would be 0.95 lag to lead power factor at the POI, meaning that the machine should be capable of injecting or absorbing the equivalent of approximately 1/3 of its active power rating (MW) as reactive power (MVAr). This lag to lead specification originated from FERC Order 2000 (Large Generator Interconnection Agreement) and was suggested by North American Electric Reliability Corporation (NERC) as a representative synchronous generator capability. In reality, synchronous generators are almost always applied with power factor measured at the terminals, not at the POI. Conventional synchronous generator reactive power capability is typically described by a “D curve” that covers the range from zero to rated output. However, it should be noted that synchronous generators are limited by the minimum load capability of the generating plant. Some conventional generators are designed to operate as synchronous condensers, allowing them to provide reactive power at zero load, but they still cannot operate between zero and minimum load. The ability to provide reactive power at zero load must be designed into the plant and it is not possible with many larger plant designs. The significance of the discussion above is that the practical reactive power capability of a typical synchronous generator is more limited than the typical “D curve” shows.

Assuming negligible auxiliary load, the corresponding power factor at the transmission interface can be easily calculated given the generator power factor at the terminals and the reactance of the generator step-up transformer. Generally, a generator with a reactive capability of 0.9 lag, 0.983 lead (measured at the generator terminals) connected to the transmission system through a transformer with a leakage reactance of 14% on the generator MVA base can provide 0.95 lag to lead at the transmission interface if the transmission system is at nominal (i.e., 100%) voltage.

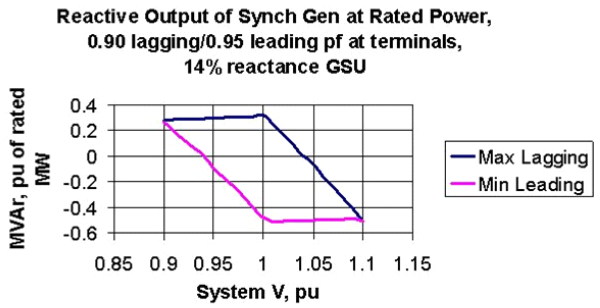

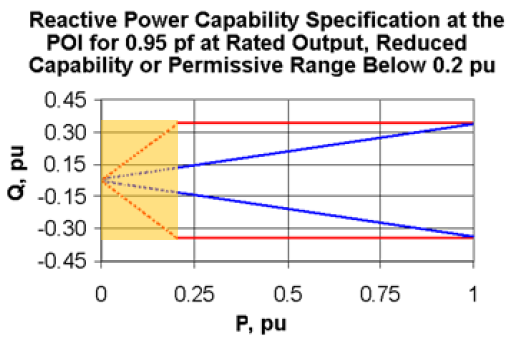

Typical specifications for synchronous generators require 0.90 lag (over-excited) and 0.95 lead (under-excited) at the machine terminals in order to allow voltage regulation at a transmission voltage range within 90% to 110% of nominal. Synchronous generators have maximum continuous voltages of 105%, and minimum continuous voltage of 95%. Depending on the system voltage and generator output level, these limits may come into play, in which case the reactive power capability would be reduced. For example, figure on the left depicts the reactive power capability at the POI for a synchronous generator at rated power with a typical reactive capability of 0.90 lag to 0.95 lead at the machine terminals, connected to the system by a 14% (on the generator MVA base) reactance step-up transformer. Note that over-excited power factor range at the POI is roughly 0.95 lag for system voltages at nominal or below, but drops off sharply at voltages above nominal. Similarly, under-excited power factor range at the POI is actually close to -0.9 lead (i.e., Q = 0.48 x P) for voltages above 100% of nominal, but the capability drops off for system voltages below nominal.

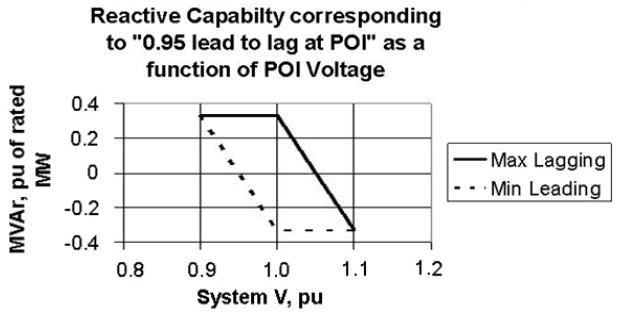

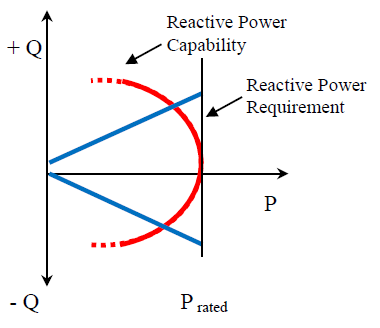

A specification of 0.95 lag to lead at full power is commonly stipulated for variable generation. However, terminal voltage limitations also affect reactive power capability of variable generators; therefore, to capture this effect, the reactive power versus voltage characteristic should be specified separately from the reactive range. For example, in addition to a 0.95 lag to lead reactive range requirement, the chart shown in figure on the right could be used to specify the reactive power capability versus voltage characteristic.

Reactive Capability or Requirements for Wind and Solar PV Generators

PV generators and some types of wind generators use power converters. The reactive capability of converters differ from those of synchronous machines because they are normally not power-limited, as synchronous machines are, but limited by internal voltage, temperature, and current constraints.

Reactive Power Capability of Wind Generators

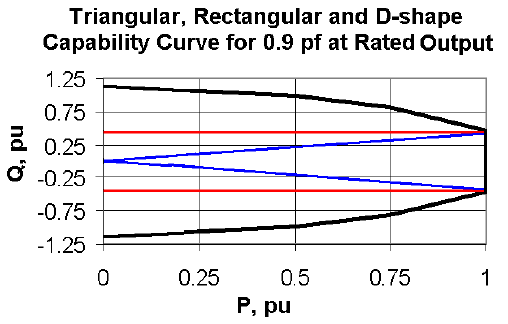

Wind generators with converter interface are often designed for operation from 90% to 110% of rated terminal voltage. Lagging power factor range may diminish as terminal voltage increases because of internal voltage constraints and may diminish as terminal voltage decreases because of converter current constraints. Leading capability normally increases with increasing terminal voltage. These characteristics also apply to PV inverters. Doubly fed and full-converter wind generators are often sold with a “triangular,” “rectangular,” or “D shape” reactive capability characteristic. This represents the reactive power capability of individual wind generators or PV inverters.

Machines with a rectangular or D-shaped reactive capability characteristic may be employed to provide voltage regulation service when they are not producing active power (e.g., a low-wind-speed condition for a wind resource or at night for a PV resource, or during curtailment) by operation in a STATCOM mode. However, this capability may not be available or may not be enabled by default. Unlike doubly fed or full-converter wind turbine generators, induction-based wind generators without converters are unable to control reactive power. Under steady-state conditions, they absorb reactive power just like any other induction machine. Typically, mechanically switched capacitors are applied at the wind generator terminals to correct the power factor to unity. Several capacitor stages are used to maintain power factor near unity over the range of output.

Reactive Power Capability of PV Inverters

_based_on_current_limit.png)

PV inverters have a similar technological design to full-converter wind generators, and are increasingly being sold with similar reactive power capability. Historically, however, PV inverters have been designed for deployment in the distribution system, where applicable interconnection standards (IEEE 1547) do not currently allow for voltage regulation. Inverters for that application are designed to operate at unity power factor, and are sold with a kilowatt (kW) rating, as opposed to a kilovolt-ampere (kVA) rating. Like inverter-based wind generators, PV inverters are typically designed to operate within 90% to 110% of rated terminal voltage. Reactive power capability from the inverter, to the extent that is available, varies as a function of terminal voltage. Furthermore, DC input voltage could also affect reactive power capability where single-stage inverter designs are used. For example, a low maximum power point (MPP) voltage could reduce the lagging reactive power capability. With the increased use of PV inverters on the transmission network, the industry is moving towards the ability to provide reactive power capability. Some PV inverters have the capability to absorb or inject reactive power, if needed, provided that current and terminal voltage ratings are not exceeded. Considering that inverter cost is related to current rating, provision of reactive power at “full output” means that the inverter needs to be larger for the same plant MW rating, which comes at a higher cost compared to existing industry practice. Figure, on the right, shows the reactive capability of an inverter based on current limits only. Based on historical industry practice, this inverter would be rated based on unity power factor operation (P1). Inverters would be able to produce or absorb reactive power when it operates at a power levels lower than P1 (e.g., P2). However, in response to recent grid codes like the German BDEW, more PV inverter manufacturers have “de-rated” their inverters and now provide both a kW and KVA rating. In principle, inverters could also provide reactive power support at zero power, similar to a STATCOM. However, this functionality is not standard in the industry. PV inverters are typically disconnected from the grid at night, in which case the inverter-based reactive power capability is not available. This practice could, of course, be modified, if site conditions dictate the use of reactive capability during periods when generation is normally off-line.

Reactive Capability of Variable Generation Plants

Reactive power requirements for interconnection are specified at the POI. This is an important consideration for wind and solar plants. First of all, it means that several technical options can be considered in the plant design to meet interconnection requirements. Technically, a plant with inverter-based wind or solar generators could rely on the inverters to provide part or all of the necessary reactive power range at the POI. It may be more economical to use external static and dynamic devices such as a STATCOM, an SVC, or mechanically switched capacitors (MSCs). The additional amount of reactive support required depends on the reactive capability of individual wind generators of PV inverters and how it is utilized. Sometimes, external dynamic reactive support is required to assist with voltage ride-through compliance.

During periods of low wind or solar resource, some generators in the plant may be disconnected from the grid. The DC voltage for solar PV inverters may limit the reactive power capability of the inverters. This should be taken into consideration when specifying reactive power capability for variable generation plants. Below a certain output level, it makes sense for the specification to show a reduced power factor range, or a permissive MVAr range.

The interconnection requirements are often applied to transmission-connected wind power plants. In the case of PV, arequirement to maintain reactive power range at full output represents a change with respect to historical industry practice. This cost impact could be substantial if the PV plant relies on the PV inverters to provide a portion or all of the required plant-level reactive power capability. Figure on the right shows the reactive capability curve for a PV-plant-based unity power factor operation (red line), and how it compares with a “triangular” reactive power requirement (blue line) that is commonly specified for transmission interconnection. In this case the PV plant would not meet the requirement at full output without adding inverter capacity, de-rating the plant, or installing external reactive power support devices. In order to achieve a power factor range of 0.95 lag to lead at the POI at rated plant output using only the inverters, the total inverter rating would have to increase by as much as 10%, considering reactive losses. It should be noted that that both PV plants and inverter-based wind plants are technically capable of providing reactive capability at full output. The difference is that such a requirement is new to the solar industry compared to the wind industry.

The requirement implied by the blue curve may not be needed for all transmission-connected PV plants. Considering that most PV plants are relatively small and the output is variable, operation along the red curve or at unity power factor may be just as beneficial to the system as operation along the blue curve. During periods where system conditions warrant, these plants could be instructed to reduce active power output such that a reactive power range can be maintained.

In addition to the reactive capability versus output level discussed above, a complete specification should address the expected reactive capability during off-nominal voltage conditions.

Static Versus Dynamic Reactive Capability

The provision of dynamic reactive capability may have cost implications different than that of static reactive capability, and thus should be separately specified. Some grid codes specify both a dynamic range and a total range of reactive operation. For example, a grid code may specify a dynamic range of 0.95 lag to lead and a total range of 0.90 lag to 0.95 lead, indicating a need for smooth and rapid operation between 0.95 lag and 0.95 lead, but allowing for some time delay for lagging power factors below 0.95. Dynamic reactive capability from converters can be provided almost instantaneously in a manner similar to that of synchronous machines, responding almost instantly (i.e., within a cycle) to system voltage variations, to support the system during transient events, such as short circuits, switching surges, etc. Fixed capacitors or reactors can be used to shift the dynamic reactive capability toward the lagging or leading side, respectively, as needed. If there is inadequate dynamic reactive capability available from the variable generation resources, it may be necessary to supplement the variable generation resources with an SVC or STATCOM.

Non-dynamic reactive sources, such as supplemental mechanically switchable capacitors or reactors, can be installed to increase total (but not dynamic) reactive capability. Breaker times are in the range of cycles, not seconds. However, once disconnected, capacitors cannot be re-inserted without first being discharged (unless synchronous switching is used). Normally, discharge takes five minutes. Rapid discharge transformers can be applied to execute discharge in a few seconds. Good engineering practice requires that consideration be given to operation of switched reactive resources. For example, it is sometimes required that lagging reactive capability be placed in service as a function of variable generation output, irrespective of system voltage conditions. A transmission operator may require, for example, that capacitors be placed in service to compensate for transmission reactive losses whenever the output of a wind park exceeds 90% of rated capability. If the system voltage is high and the turbines are already operating at the leading power factor limit, placing capacitors in service may cause a high transient and steady-state overvoltage that can result in turbine tripping and other operational difficulties. It may be necessary to adjust transformer taps to bias turbine voltages in a safe direction if such operation is necessary.

Operational Considerations

Reactive capability on transmission systems is typically deployed in voltage regulation mode. The transmission system operator provides a voltage schedule and the generator (conventional or variable generation) is expected to adjust reactive output to keep the voltage close to the set point level. Normally this is done by regulating the resource’s terminal voltage on the low side of the resource’s main transformer. Another emerging practice is to adjust reactive output per a “reactive droop” characteristic, using the transmission voltage. Reactive droop in the range of 2% to 10% is typically employed. A typical droop of 4% simply means that the resource will adjust reactive output linearly with deviation from scheduled voltage so that full reactive capability is deployed when the measured voltage deviates from the scheduled voltage by more than 4%. A 1% deviation results in 25% of available reactive capability being deployed, etc. A voltage deviation less than the deadband limit would not require the resource to change reactive power output.

The specifications of the reactive droop requirement (e.g., the deadband of the droop response, together with the response time to voltage changes) may lead to requirements for dynamic reactive power support as well as potentially fast-acting plant controller behavior. Reactive droop capability is an emerging capability for solar PV plants, although there are no technical impediments to the implementation of such a control schemes. Individual wind generators and solar PV inverters typically follow a power factor, or reactive power, set point. The power factor set point can be adjusted by a plant-level volt/var regulator, thus allowing the generators to participate in voltage control. In some cases, the relatively slow communication interface (on the order of several seconds) of inverters limits the reactive power response time.

Reactive droops of less than 2% for voltage regulation on the transmission system are essentially “bang-bang” voltage controls that may introduce oscillations, cause excessively rapid voltage fluctuations, and deplete reactive reserves for contingencies. They may be necessary in some weak systems, but they should generally be avoided, if possible. For large plants connected to the transmission system, reactive power control (fixed Q) and power factor control (fixed ratio of Q to P) is not generally used because they can result in inappropriate response to system voltage fluctuations and they generally detract from local system voltage stability. However, it should be noted that reactive control or power factor control are reasonable options when connected to a very stiff bus relative to the plant size. This is an important consideration in anticipation of smaller plants needing to be addressed in NERC standards. Moreover, reactive power control or power factor control are appropriate for distribution-connected generators.

Review of Existing Reactive Power Standards

The following sections discuss the key reactive power requirements applicable in North America and Internationally.

Standards Applicable in North America

FERC

FERC Order 661A applies specifically to wind farms with aggregated nameplate capacity greater than 20 MVA. Wind generation plants are generally required by transmission operators to provide a 0.95 lag to lead power factor range at the point of interconnection, and voltage regulation functionality. Order 661A places the burden on the transmission operator to establish the need for a power factor requirement up to the 0.95 lag to lead power factor range, and the need for dynamic reactive capability. Some transmission operators would prefer to interpret Order 661-A as a baseline requirement based on a system-level need, and not on a case-by-case basis. There is still a great deal of uncertainty regarding this issue for all types of variable generation. Furthermore, there are different interpretations and a lack of clarity regarding the amount of dynamic versus static reactive power that is required, with Order 661-A requiring that wind farms provide sufficient dynamic voltage support in lieu of power system stabilizer (PSS) and automatic voltage regulator (AVR). FERC’s interconnection requirements currently do not contain language that applies to solar generation. However, generation interconnection procedures in California were recently revised to incorporate provisions similar to FERC Order 661A, but applicable to all asynchronous generators.

NERC

Applicability of NERC standards to generators is defined in NERC’s Criteria Statement of Compliance Registry Criteria (Revision 5.1). Generators larger than 20 MVA, a plant/facility larger than 75 MVA in aggregate, any generator that is a blackstart unit is subject to NERC standards. Regional standards and other requirements supplement the NERC standards. An important consideration is that NERC standards, unlike some regional grid codes, strive to be technology neutral. A good example of this philosophy is the PRC-024 standard on voltage and frequency tolerance, which is currently being drafted.

NERC FAC-001 directs the transmission owner to define and publish connection requirements for facilities, including generators. The connection requirements must address reactive power capability and control requirements (R2.1.3 and R2.1.9). As stated in the previous section, the manner in which reactive power capability may be used affects interconnection requirements. In that regard, NERC VAR standards address operating requirements with respect to reactive power control, although the language used is more pertinent to synchronous generation and could be modified to better address variable generation. VAR-001 R3 states that “The Transmission Operator shall specify criteria that exempt generators from compliance with the requirements defined in Requirement 4, and Requirement 6.1.” VAR-001 R4 and R6.1 refer to requirements to operate in automatic voltage control or reactive power control. VAR-002 indicates that generators with automatic voltage regulators must operate in voltage control mode unless directed otherwise by the transmission operator.

Interconnection standards issued by transmission operators pursuant to FAC-001 are not uniform. Some transmission operators address the reactive power requirements explicitly, and some just refer back to the FERC pro-forma LGIA/SGIA. For example, the Idaho Power statement of compliance with NERC’s FAC-001 states in Section R2.1.9 that “IPC’s voltage, reactive power, and power factor control requirements for generators are described in its generator interconnection agreements. The requirements for generators larger than 20 MW are listed in section 9.6 of IPC’s Standard Large Generator Interconnection Agreement (LGIA). For generators smaller than 20 MW, section 1.8 of IPC’s Small Generator Interconnection Agreement (SGIA) describes the requirements.” In contrast, the Pacific Gas and Electric Company (PG&E) Generation Interconnection Handbook states in Section G3.1.2.2 that “Wind generating facilities must provide unity power factor at the point of interconnection (POI), unless PG&E studies specify a range. PG&E may further require the provision of reactive support equivalent to that provided by operating a synchronous generator anywhere within the range from 95 percent leading power factor (absorbing Vars) to 90 percent lagging power factor (producing Vars) within an operating range of ±5 percent of rated generator terminal voltage and full load. (This is typical, if the induction project is greater than 1,000 kW.)” Further, in G3.1.3, the PG&E document states that “Inverter-based generating facilities need to provide reactive power (Vars) to control voltage. It shall be measured at the facility side (generally the low voltage side) of the step-up transformer that connects to PG&E. The facility reactive capability shall be at least capable of providing 43 percent of facility Watt rating into the system and capable of accepting 31 percent of facility Watt rating from the system.” Other standards related to reactive power capability are reviewed below.

ERCOT

ERCOT Generator Interconnection or Change Request Procedures apply to single units larger than 20 MVA or multiple units (such as wind and solar generators) with aggregated capacity of 20 MVA connected to the transmission system. The required power factor range is 0.95 lag to lead at maximum power output and must be supplied at the POI (transmission). At partial power, reactive capability must be up to the MVAr range at rated power, or at least the required range at rated power scaled by the ratio of active power to rated power. The reactive range must be met at the voltage profile established by ERCOT. All generators are required to follow a voltage schedule, within the reactive capability of the generator, and operate in voltage regulation mode unless otherwise directed by ERCOT at power output levels equal to or greater than 10% of rated output.[2]

California Independent System Operator

The California Independent System Operator (CAISO) recently proposed more detailed power factor requirements that apply to all forms of “asynchronous generation” (including wind and solar). The proposed requirement was a 0.95 lag to lead power factor baseline requirement at the POI. A parallelogram was used to specify reactive power capability versus voltage. The proposed standard also would have allowed a permissive reactive range when the generating facility output is below 20% of rated active power output. It also stated that the reactive power must be met at full real power output, and clarified that the reactive power capabilities could be met with external static or dynamic reactive power support equipment. Specific requirement for automatic voltage regulation included definitions for voltage deadband and response time. FERC rejected the CAISO proposal on the grounds that baseline reactive power requirements should be justified by a specific interconnection study.

HECO

The Hawaiian Electric Company (HECO) currently is determining the power factor requirements through the interconnection agreement and Power Purchase Agreement process, including for sites below 20 MW. The requirements are similar to that proposed by other bodies, with indications that a VAR requirement (that corresponds to 0.95 power factor at rated power) would be satisfactory in place of a power factor requirement.

AESO

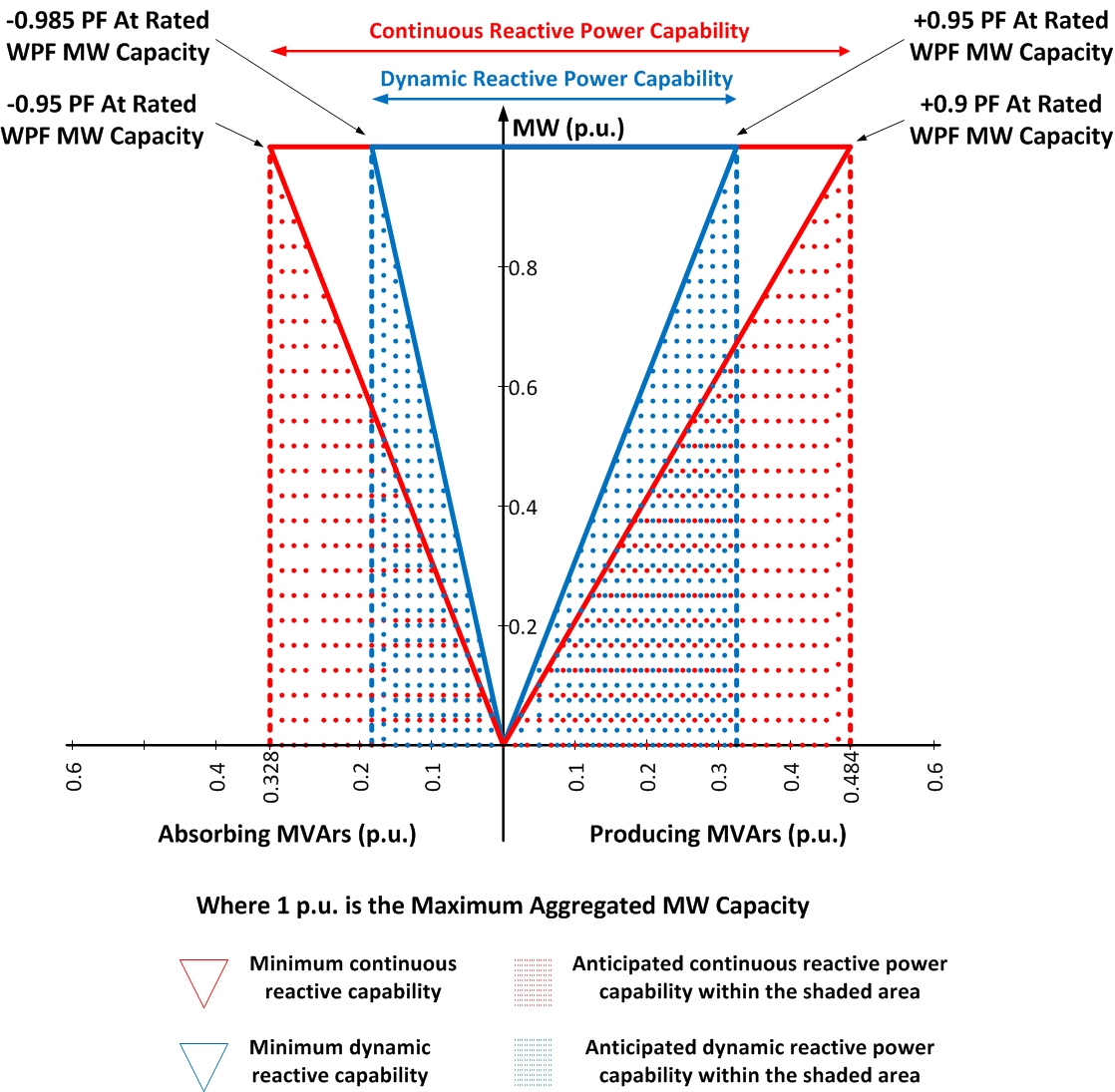

The Alberta Electric System Operator (AESO) specifies reactive power requirements for wind generators, as shown in figure on the right. The basic requirement is that sustained reactive power capability shall meet or exceed 0.9 lag to 0.95 lead power factor based on the aggregated plant MW level. A portion of the reactive capability, 0.95 lag to 0.985 lead must be dynamic. Short-term reactive power capability that can be sustained for one second or longer counts toward the required dynamic reactive power capability. Subject to review and approval of the AESO, several wind plants connected to a common transmission substation may consider aggregating voltage regulation and reactive power from a single source to meet the overall reactive power requirement. The intent of voltage regulation requirements is to achieve reasonable response to disturbances as well as a steady-state regulation of +/- 0.5% of the controlled voltage. The standard identifies a minimum requirement for dynamic reactive power and permits some controlled reactive devices such as capacitor banks to satisfy total reactive power requirements. The reactive power performance and voltage regulation is assessed at the low-voltage side of the transmission step-up transformer(s), and at rated collector system voltage.

Reactive Power Requirements Applicable to Distribution Interconnection System

In North America, distribution interconnections generally conform to IEEE 1547 standards, as codified in FERC’s Standard Generator Procedures (SGIP) and state-level interconnection processes. With respect to reactive power, IEEE 1547.1 states that output power factor must be 0.85 lag to lead or higher; however, distribution-connected PV and wind systems are typically designed to operate at unity or leading power factor under power factor control and can provide little or no reactive capability at full output. Operating in voltage control, often required for transmission connected generation, is not permitted under IEEE 1547.

Summary

| Summary of Existing Reactive Power Standards | |||||

|---|---|---|---|---|---|

| Standard | Technology Addressed | Power Factor Requirements | Voltage Range | Equipment Specified (Static/Dynamic) | Control Modes |

| FERC 661A – Appendix G | Wind Plants | 0.95 lag to lead at point of interconnection (POI), burden of proof required from Transmission Provider | Not Specified? | By means of power electronics within the limitations due to voltage level and real power output or fixed and switched capacitors as agreed by the transmission provider | Not Addressed |

| NERC FAC-001 | Generators larger than 20 MVA, plant/facility larger than 75 MVA in aggregate, any generator that is a blackstart unit, and any generator connected to the bulk transmission system (typically 100 kV and above). | Directs the transmission owner to define and publish connection requirements. The connection requirements must address reactive power capability and control requirements. Interconnection standards issued by transmission operators pursuant to FAC-001 are not uniform. | Not Specified? | Not Addressed | VAR-001 R4 and R6.1 refer to requirements to operate in automatic voltage control or reactive power control. VAR-002 indicates that generators with automatic voltage regulators must operate in voltage control mode unless directed otherwise by the transmission operator. |

| ERCOT | Single units larger than 20 MVA or multiple units (such as wind and solar generators) with aggregated capacity of 20 MVA connected to the transmission system. | The required power factor range is 0.95 lag to lead at maximum power output and must be supplied at the POI (transmission). At partial power, reactive capability must be up to the MVAr range at rated power, or at least the required range at rated power scaled by the ratio of active power to rated power. | The reactive range must be met at the voltage profile established by ERCOT. | All generators are required to follow a voltage schedule, within the reactive capability of the generator, and operate in voltage regulation mode unless otherwise directed by ERCOT at real power output levels of 10% and higher. | |

| CAISO (Proposed) | All Variable Energy Generation | 0.95 lag to lead (consuming/producing) at POI when variable generation resources (VER) is exporting >20% of maximum rated power to the POI. Maximum VAR is a function of real power delivered (triangle VAR support above 20% rated capacity). Example, a VER is exporting 10 MW to the POI, the VER should be capable of injecting or absorbing up to 3.3 MVAr at the POI. | Ability to provide the full range of reactive power support at voltages between 0.95 and 1.05 pu was initially proposed but is under review. | By means of inverters, switched or fixed capacitors, static devices (STATCOM) or a combination of these sources. | Voltage control mode is default with ability to operate in power factor control mode. Per Western Electricity Coordinating Council requirements. Regulate voltage at POI under steady state and disturbance conditions, per the voltage schedule by use of Automatic Voltage Control System (AVCS). All reactive power devices must be controlled by AVCS. No mention of dynamic voltage support or time response. Within the limits of the rating of the equipment. |

| HECO (PPA Example) | Under negotiation | Minimum 0.95 lag to lead within the limits of the reactive power range at full apparent power. | Specified at Nominal Voltage | Reactive response speed (site-specific). | |

There are several good examples of interconnection standards that apply to interconnection of variable generation in Europe and elsewhere.

International Standards

Some examples are provided below.

Wind Generation “Grid Codes” in Europe

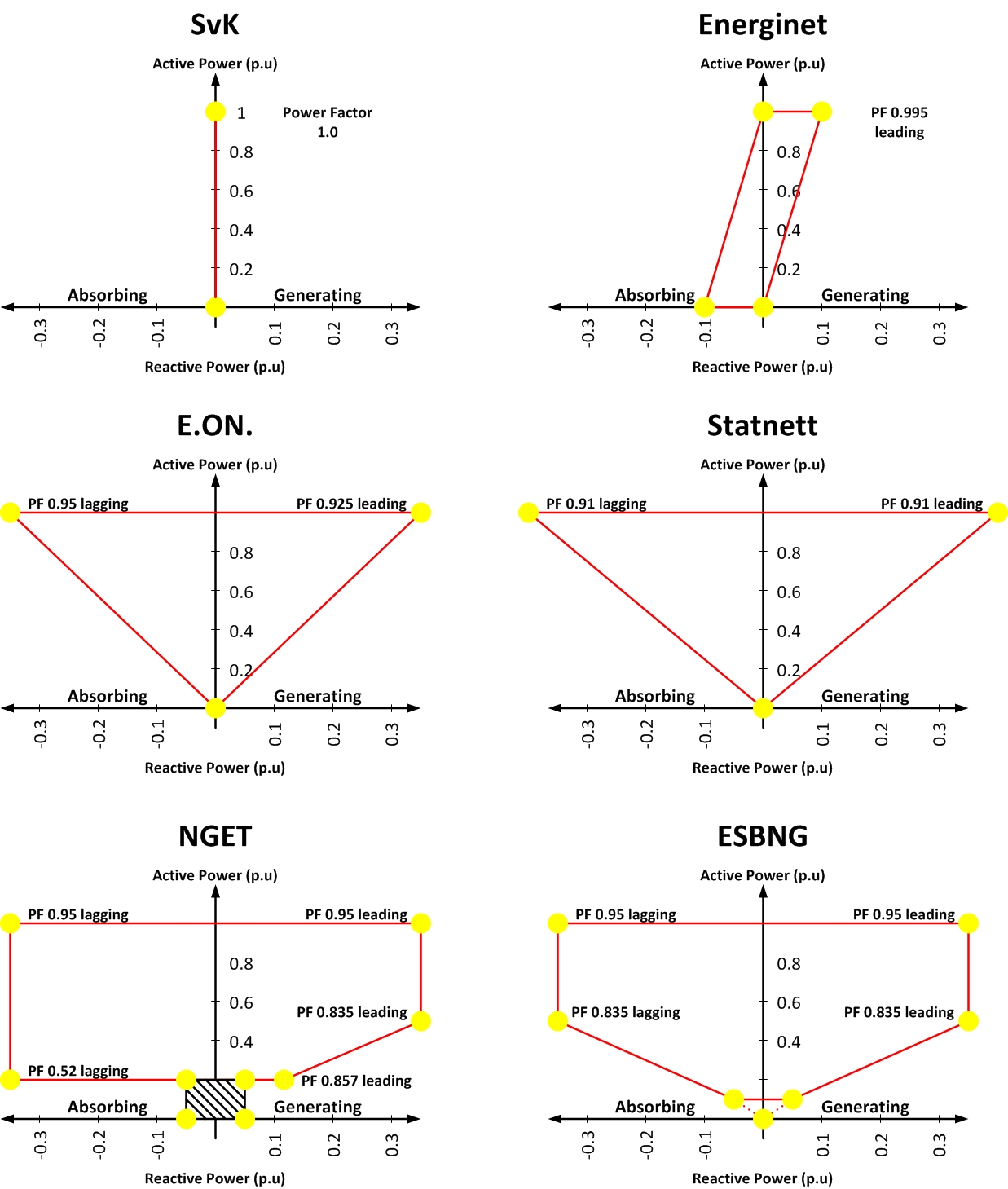

In Europe, interconnection standards for wind generation, known as “grid codes,” are relatively mature compared to standards in North America. Standards vary across transmission operator jurisdictions, and there are efforts underway to harmonize the format of the standards. Power factor design requirements are expressed as a Q versus P capability curve. Some examples are provided in figure on the right. These charts specify reactive power requirements across the full operating range of active power, not only at full output. As a point of reference, power factor design requirements at full output vary between unity and 0.9 under/over excited at the point of connection. Most codes recognize that reactive power capability depends on voltage conditions, and contain specifications to that effect.

Some grid codes specify the portion of the capability curve that must be dynamic, similar to the AESO standard (Alberta). Some grid codes discuss how this reactive capability may be utilized in operations (voltage/droop control, power factor control, and reactive power control), and the expected response time for each. Some grid codes also discuss the control strategy required during fault conditions, which could play a role in the system design and equipment selection.

Medium Voltage Standards in Germany

Interconnection requirements for solar PV systems installed at medium voltage (10 kV to 100 kV) were recently put into effect in Germany. The power factor design criterion is 0.95 lag to lead at full output, which requires inverters to be oversized or de-rated. This standard also requires dynamic reactive power support during voltage excursions.

References

- ↑ Sandia NL, Reactive Power Interconnection Requirements for PV and Wind Plants (SAND2012-1098), February 2012, [Online]. Available: http://energy.sandia.gov/wp/wp-content/gallery/uploads/Reactive-Power-Requirements-for-PV-and-Wind-SAND2012-1098.pdf. [Accessed May 2013].

- ↑ ERCOT Planning Guides, [Online]. Available: http://www.ercot.com/mktrules/guides/planning/current.html. [Accessed May 2013]